As I'm typing this blog post, I'm drinking the Mardi Bock that I brewed on Super Bowl Sunday.

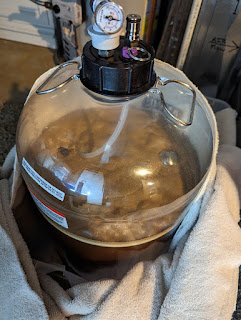

You may recall (if you read that article) that this is the first (and so far the only) batch on which I've used my new 7.9 Gallon Fermenter King Chubby.

I got the "Chubby" because I thought it would be fun / interesting / educational to try Pressure Fermentation.

Pressure fermentation is the process of fermenting beer inside a closed and pressurized vessel.

Typical fermentations allow CO2 to escape the fermenter through an airlock or blow-off tube. In pressurized fermentation, the fermenter is sealed and the CO2 produced by the fermentation is trapped inside.

You can't just let all the pressure remain in the fermenter, you need a valve that allows pressure to escape above a certain psi. This valve is called a "spunding" valve.

Well ....

Lots of brewers claim that by fermenting under pressure you can suppress esters, and therefore ferment at higher temperatures than you would normally to get "clean" beers.

This is particularly useful when it comes to lagers. Supposedly you can ferment at room temperature and still get the clean lager-like fermentation you would at lower temperatures.

Temperature control isn't as important.

Another advantage over "standard" fermentation is that when you're fermenting under pressure, some of the CO2 gets trapped in solution and you have a head-start on carbonation.

In my mind, the main advantage of using a fermenter that can hold pressure is that it is easier to transfer beer from the fermenter to the keg without introducing oxygen.

You can use the naturally produced pressure to push the beer from the fermenter to the keg. If that isn't enough, you can use a CO2 tank.

So ... there is no need to open the beer to oxygen so there is less chance to start the oxygen spoilage.

Anyway ... I brewed my Mardi Bock under pressure. I started the fermentation at lager temperatures, but didn't keep it cold, and so most of the fermentation was at room temperature.

And the fermentation went well. The spunding valve was sort of hard to precisely set, but that wasn't a major issue.

I don't think the fermentation was necessarily faster at the higher temperature, but I don't really care.

I was really excited when I got to the point when I was getting ready to transfer to a keg.

When I was at my local homebrew shop to pick up ingredients to brew Dubbel Minor I picked up a liquid to liquid transfer tube.

And ... I screwed up the pressure transfer. I wasn't even drinking, so I can't blame alcohol. I was just an idiot.

Take a look at any of the last 3 pictures in this post. The spunding valve is connected to the "gas out" side of the fermenter. The other side is connected to a tube with a floating dip tube to transfer beer from the top of the liquid.

So ... I connected my transfer tube on the wrong side. I disconnected the spunding valve and connected my transfer tube to the gas side.

Nothing moved from the fermenter to the keg. (obviously)

Rather than think about why nothing was moving, I figured there was not enough pressure to get started and I connect my CO2 tank to my liquid post.

And that pretty much just agitated the beer and put the trub into solution.

It still took me a bit to understand my mistake, but eventually I got there. I got the beer into the keg along with way too much "crap" / trub.

Also, I ended up subjecting the beer to the oxygen that pressure transfers are supposed to protect the beer from.

Oh well. Next time.

The beer I'm drinking is good, but it will take awhile for this to clear up.

Bottom line, I next time I need to pay closer attention.

No comments:

Post a Comment